Quality Assurance

At IMW, quality is a primary business principle that ensures clients are completely satisfied both in the quality of the order and its timely delivery. Each and every IMW employee adheres to this principle to make a quality product for our customers. All of our quality assurance programs are developed, reviewed and evolved with input from our team – all part of a continuous improvement effort.

We ensure accuracy by…

- Certified quality management

- In-process controls

- Highly qualified personnel

- Continuous improvement

Certified quality management system

Total customer satisfaction is paramount, so we take extra measures to ensure the quality of our work by insisting on continuous improvement in our processes and in the skills of our people. To that end, we’re certified to IATF 16949 : 2016 First Edition. This certification takes considerable time and effort and along with this designation comes regular audit review process to maintain our high level of quality standards.

The IATF 16949 technical specification touches all parts of the process, including a quality management system that emphasizes defect prevention and reducing variation and waste in the supply chain.

Click on the Link to see our new Certificate

Controlled Goods Certificate has been renewed for any upcoming Defense / Military requirements through Public Works and Government Services Canada

Click here to view our CONTROLLED GOODS Certificate

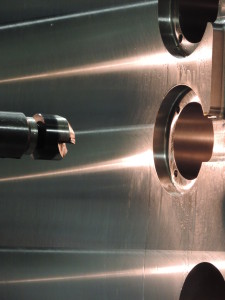

In-process controls

In the business of custom machining, constant, in-process scrutiny is key to ensuring you get what you order: components that meet all of the specifications on the drawing. In that, we employ visual checks, check sheets, weekly audits to review processes and precision measuring capabilities.

Highly qualified personnel

We pride ourselves with our personnel, all of whom are highly skilled and experienced. The skilled trades participate in developing the most efficient production process, provide ideas to reduce set-up times and practical applications of continuous improvement theory. Our team functions in a culture of innovation so we can find the best, most cost-effective machining solutions for you.

Continuous improvement

Clients appreciate IMW’s approach to quality assurance, in which continuous improvement is an integral part. For us, each project is unique – demanding a unique approach – right from high level, strategic planning to the shop floor.

IMW has implemented continuous improvement as the main component of our quality assurance program to ensure that first, we recognize our customers’ quality requirements and then implement a process that’s custom-designed to deliver it. The process includes ways to promptly detect discrepancies to enable timely and effective corrective action.

A key aspect of any continuous improvement program is the comprehensive approach and analysis of accurate manufacturing performance data it is also a review of the process and ways to eliminate waste. At its most basic level within IMW manufacturing environment Continuous Improvement involves a review on rework, inventory, unreliable equipment, quality issues and any unnecessary processes and additional labour.