Our Services

Capable people using cutting edge equipment for custom manufactured components

IMW operates a full-service, complete-source facility that can deliver a turnkey solution, a total system for machining/tooling manufacturing. We’re committed to delivering quality products at a competitive price meeting your needs in this ‘just-in-time’ world.

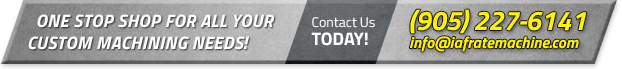

The skilled IMW team understands the specifications required by our clients and is committed to delivering a broad range of components that meet your custom manufacturing needs – on time and on budget. We’re custom manufacturers who employ the latest in CNC turning and milling equipment with experience working on a wide spectrum of materials to produce the top quality components to satisfy our customers needs.

CNC is a versatile system enabling control of the motion of tools and parts using computer programs built on numeric data. It can be used with nearly any traditional machine. IMW employs the finest turning centres and vertical and horizontal machining centres, giving us the capability to perform virtually any machining operation with the highest level of accuracy and repeatability.

Essentially, the skilled IMW team is equipped to be – and aims to be – your most reliable partner.

We respond to your needs with…

- A focus on service

- A commitment to quality

- An aim to meet our customers requirements

Our overall approach is simple: we provide rapid turn-around of components at a competitive price – all with a total commitment to customer satisfaction.

Focused service

We recognize that people and relationships drive business. From the very first contact to final order delivery, IMW team members are focused on ensuring your people get the information they need. If you have any questions, do not hesitate to give us a call and we’ll direct you to the IMW team member who can deliver a rapid and comprehensive response.

Committed to quality

We know how important your products are to your business and we’re committed to meeting and exceeding your quality standards.

IMW employees adhere to this principle to make a quality product for our customers. All of our quality assurance programs are developed, reviewed and evolved with input from our team – all part of a continuous improvement effort. We are certified to IATF 16949: 2016, First edition

Meeting unexpected requirements

At IMW, we are committed to meeting our customers’ needs by effectively planning for the unexpected. Why? Because helping you respond quickly to your customers, strengthens those critical relationships, which improves your confidence in us. That’s a win-win situation for all concerned.

Creative solutions to complex problems

We employ knowledge capital – and a full range of resources – for every job that comes in the door.

- Besides working to the tolerances our clients rightly expect, IMW prides itself on devising innovative ways to cut costs – by streamlining load and unload times, among other things. Creating efficient processes to allow the finished part to emerge, and at the same time the next one is inserted into position for machining.

- At IMW, we can utilize robotics, conveyors and other means to handle your specific order, effectively and efficiently. Automation and controlled processes enable one technician to monitor multiple machines at once – keeping costs down and delivering a competitive advantage.

- Another part of our competitive advantage is keeping supplies of quality raw materials on hand.

- When required, IMW can reverse-engineer a component, complete the drawings and quote the part.

- When it comes to forgings, IMW is one of the few manufacturing companies that can not only make the die, but will also arrange for the appropriate forging company to produce the forgings and in turn have IMW final-machine the forging to customer specifications and ship to the customer. It’s part of our customer service to manage the process and warehouse the appropriate materials, essentially holding a safety stock of inventory for you, to ensure continuing orders are produced and shipped in a timely fashion.

CNC Prototype Machining

One thing IMW recognizes as being critical to growing your business is getting to market – quickly. It’s why we specialize in rapid turn-around for your CNC prototype machining needs. Ideally, we’ll work with your prototype designs but when that’s not available, we’re here to provide the kind of advice that will transform your concept into reality. Quickly. Accurately.

Call or email us about your CNC prototype machining requirements and let us show you our capabilities. You’ll be glad you did.

Project Management

Part of the key to our superior service is IMW’s project management process. The manufacture and finishing of parts and assemblies typically requires several operations and treatments. Coordinating these processes can become a challenge when you are managing your own production and distribution processes.

Let IMW become your single-source, turnkey supplier, reducing time and expense in managing the details of getting a finished product out on time – all under the control and monitoring of our stringent quality assurance program.

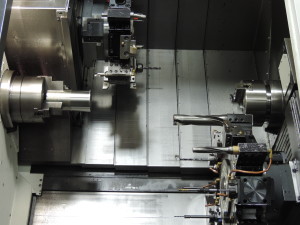

CAD / CAM Software

Autodesk

AutoCAD Professional 2014

AutoCAD Inventor Professional 2014

IMW Uses the latest AutoDesk Software which can provide 2D and 3D drawings and models for projects that cover the entire spectrum of IMW’s output. Our drawings and output comply with our corporate image and in accordance with our accredited quality assurance systems, ensuring consistency and quality.

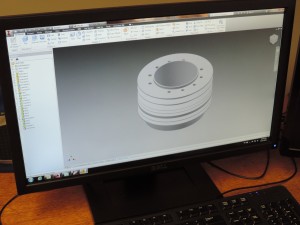

Delcam

FeatureCAM 2012

Exchange 2012

Delcam FeatureCAM is a computerized automated machining process, minimizing programming times and increasing productivity. FeatureCam quickly creates reliable and consistent tool paths based on the features of the part, while intelligently selects the appropriate tools, roughing and finishing paths, and calculates feeds and speeds based on the software’s built-in machining knowledge for the part being manufactured. Integrated 3D machine simulations, together with a library of over 350 fully customizable post-processors, lets you visualize exactly how your parts will be machined.

Sescoi

WorkNC V96

WorkNC is automatic CAM software that enhances all design and manufacturing systems by providing the most reliable, efficient, easy-to-program cutter paths on molds, dies and models. Given a series of cutters and a few basic parameters, WorkNC automatically determines efficient methods of roughing, finishing and corner clean-out tool paths where previous cutters may have left stock.

Other

IMW also uses Camax, Camand V14, Anvil and Omtronix.